What is a Wafer Ball Valve?

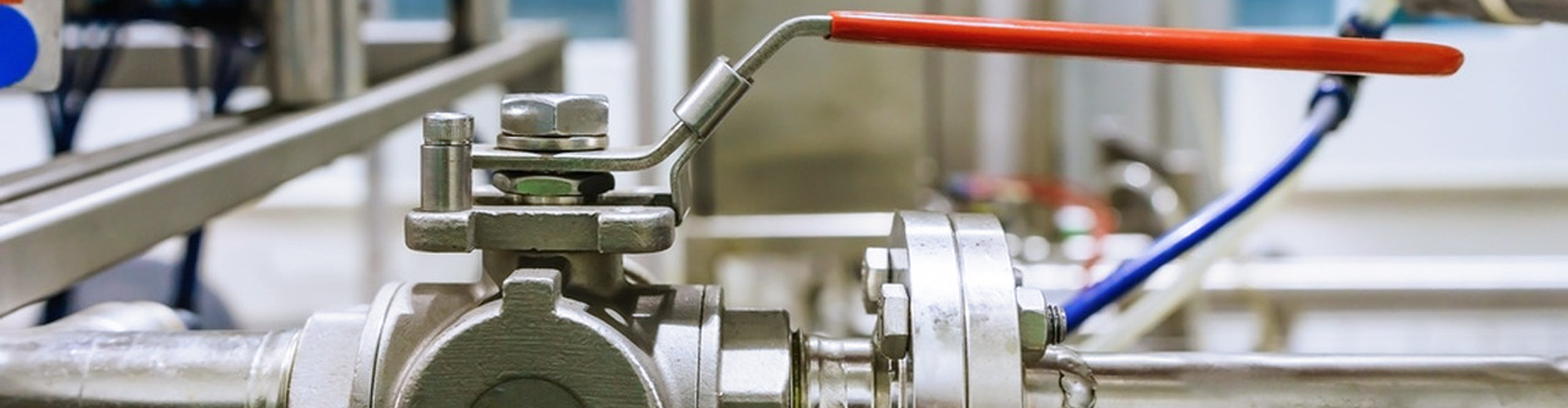

A wafer ball valve is a highly efficient and space-saving valve designed to manage fluid flow with a simple quarter-turn rotation of a perforated ball. Its name comes from its thin, "wafer" style body, which is installed between two flanges using long bolts that extend through the entire valve body. This compact, lightweight design makes it the ideal solution for applications where installation space is at a premium, without compromising on robust performance and reliability.

Feature Box

ISO 5211 Mounting Pad

All of our wafer ball valves feature an integrated mounting pad that conforms to the ISO 5211 standard, enabling seamless and straightforward automation with a wide range of pneumatic or electric actuators.

Actuation Options

Choose from manual levers, gear operators, and advanced electric or pneumatic actuators to achieve the level of control and automation your system requires.

Customizable Ball Orifice

The ball orifice can be structured as O-port, V-port, curved port, or rectangular port according to customer requirements to control flow operation.

Application

Oil & Gas

Our Wafer Ball Valves play a crucial role in oil and gas pipeline systems with their rugged, bi-directional sealing design. Their ability to reliably control the flow of crude oil, natural gas, and refined products is essential for safe operations. The compact structure is also a significant advantage for installations on space-limited platforms and in refineries, ensuring stability and safety.

Chemical Processing

In chemical processes that handle corrosive or hazardous media, selecting the right valve is paramount. Our Wafer Ball Valves provide excellent sealing performance and can be configured with a variety of materials to safely manage aggressive media. The customizable ball orifice structure (such as a V-port or O-port) also allows for precise flow regulation, ensuring accurate control for complex chemical reactions.

Water & Wastewater Treatment

Our valves are the ideal solution for shut-off and regulation in municipal water, wastewater treatment, and industrial water circulation systems. Their lightweight design makes installation and inspection of large pipe networks more efficient. The bi-directional sealing capability is critical for preventing backflow, ensuring water purity and system stability.

Product Advantages

High-Performance Efficiency:

The simple quarter-turn operation allows for fast and precise flow control. With an optimized flow path, our ball valves minimize pressure drop, which boosts overall system efficiency and can lead to energy savings.

Compact & Lightweight Design

The innovative wafer-type body significantly reduces the valve's size and weight compared to traditional flange-end valves. This not only saves valuable installation space but also simplifies handling, shipping, and maintenance.

Bi-directional Sealing

Our valves are engineered with a durable seat design that provides a secure, leak-proof seal in both flow directions. This ensures superior performance and enhanced safety, minimizing the risk of media leakage.

Versatile Integration & Easy Maintenance

Designed with an integrated ISO mounting pad, our wafer ball valves can be easily automated with various actuators. Their robust yet simple construction with fewer components makes them highly reliable and easy to service, reducing downtime and operational costs.

Ready to Enhance Your Fluid Control

Discover your ideal wafer ball valve solution. Whether you need a standard valve or a customized solution for a complex system, our expert team is ready to help you find the perfect fit.

Related Blogs

-

When I look at butterfly valves, I see different types. These types depend on how they work and how they are made. The main ways to sort these valves are by disc alignment, body or connection style, seat or lining material, actuation method, and the material used. These types help me pick the rightIndustry News

When I look at butterfly valves, I see different types. These types depend on how they work and how they are made. The main ways to sort these valves are by disc alignment, body or connection style, seat or lining material, actuation method, and the material used. These types help me pick the rightIndustry News -

Wafer type ball valves are a popular choice in various industries due to their compact design and versatile functionality. These valves are specifically designed to control the flow of fluids by utilizing a ball with a hole in the center. The main advantage of wafer type ball valves is their space-saving design, which allows for easy installation between flanges.Industry News

Wafer type ball valves are a popular choice in various industries due to their compact design and versatile functionality. These valves are specifically designed to control the flow of fluids by utilizing a ball with a hole in the center. The main advantage of wafer type ball valves is their space-saving design, which allows for easy installation between flanges.Industry News -

Wafer type ball valves are essential in various industries due to their compact design, tight shut-off, excellent flow control capabilities, durability, and ease of maintenance. They can enhance operations, improve safety, and optimize overall performance. Proper installation is crucial, including alignment, selection of suitable gaskets, and thorough testing. Following manufacturer's guidelines is important to ensure a tight seal and prevent leakage. Regular maintenance, such as inspection, lubrication, cleaning, and prompt issue addressing, is vital for optimal performance and longevity. Proper storage and handling are also crucial. Following these expert tips and seeking professional assistance when needed can guarantee the smooth operation of wafer type ball valves and minimize the risk of costly repairs or replacements.Industry News

Wafer type ball valves are essential in various industries due to their compact design, tight shut-off, excellent flow control capabilities, durability, and ease of maintenance. They can enhance operations, improve safety, and optimize overall performance. Proper installation is crucial, including alignment, selection of suitable gaskets, and thorough testing. Following manufacturer's guidelines is important to ensure a tight seal and prevent leakage. Regular maintenance, such as inspection, lubrication, cleaning, and prompt issue addressing, is vital for optimal performance and longevity. Proper storage and handling are also crucial. Following these expert tips and seeking professional assistance when needed can guarantee the smooth operation of wafer type ball valves and minimize the risk of costly repairs or replacements.Industry News

Keep in Touch With Us

If you have any questions or requirements regarding wafer ball valves, please feel free to contact our customer service team. Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-13857771712

E-mail:pioneertrade@163.com